Do you know the road signs and their meanings? Road accidents have become very frequent on our roads in recent times. It is therefore highly important to know about road Signs and their meanings in Ghana. These signs when strictly obeyed will help curb road accidents in Ghana.

The next time you drive into a new town or country, look for the road signs. The simple DVLA road sign is one of the most effective tools in helping travellers get where they need to go.

While it’s easy to dismiss this seemingly-innocuous piece of everyday transportation equipment, consider that every element on that sign has been carefully considered and placed there for a reason.

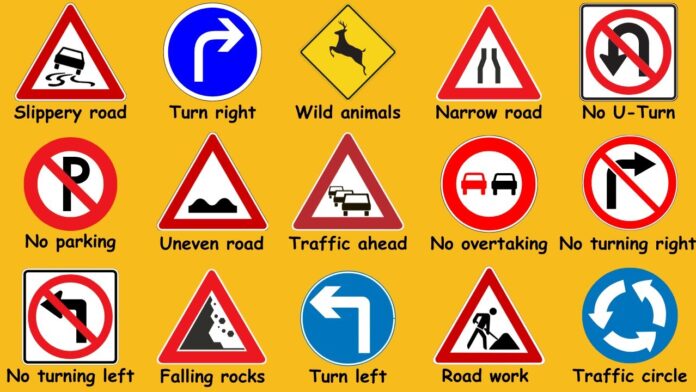

This post will help you discover all the road signs in Ghana and their meaning. Knowing these road signs will help reduce traffic accidents in the country.

Road traffic accidents are one of the leading causes of death in Ghana. Road accident is a major public health problem that affects many countries worldwide.

Hello there! Kindly share this post on all your social media pages to help someone understand the road signs and their meaning in Ghana to help save lives this year.

Watch A Video Of Road Signs And Their Meaning

What Are The 3 Types Of Road Signs And What Do They Mean?

The DVLA road signs are grouped into 3 main categories. These include:

- Regulatory Signs

- Warning Sings

- Informative Road Signs

The 3 Types Of Road Signs And Their Meanings

Regulatory Signs

Regulatory signs are a mandatory provision as guided by the Accra Metropolitan Authority. For example, the traffic signals; red, yellow and green lights are examples of regulatory signs, also known as directive signs.

Regulatory traffic signs follow international conventions, usually being:

- White circle or rectangle with a red border, with a black pictogram, black text, or both

- Blue circle or rectangle with white border and white pictogram

- Red rectangle with white border and white text

- Red octagon with white border and white text

Warning Sings

A warning sign is a type of sign which indicates a potential hazard, obstacle, or condition requiring special attention. Some are traffic signs that indicate hazards on roads that may not be readily apparent to a driver.

While warning traffic sign designs vary, they usually take the shape of an equilateral triangle with a white background and thick red border. Some warning signs have flashing lights to alert drivers of conditions ahead or remind drivers to slow down.

Informative Road Signs

Informative Road Signs (traffic signs) tell us about available services on the road or next to the road. Also, they provide information related to places along the highway or coming up next, sometimes along with their distance from the current location. Informative signs are rectangular.

DVLA Road Signs And Their Meaning In Ghana

Conclusion

Accidents do happen, and they are miserable. However, it is crucial to find ways to prevent them from reoccurring. At Hospitalitygh.com, we aim to provide tips on staying safe when travelling in the country. Hopefully, you’ve found these tips helpful!

The best way to avoid being involved in a motor accident is to be careful on the road. This was a simple article about how you can do that when observing all the DVLA road signs and their meaning. If you like this content and want to see more, please feel free to keep visiting our site for more exciting information.